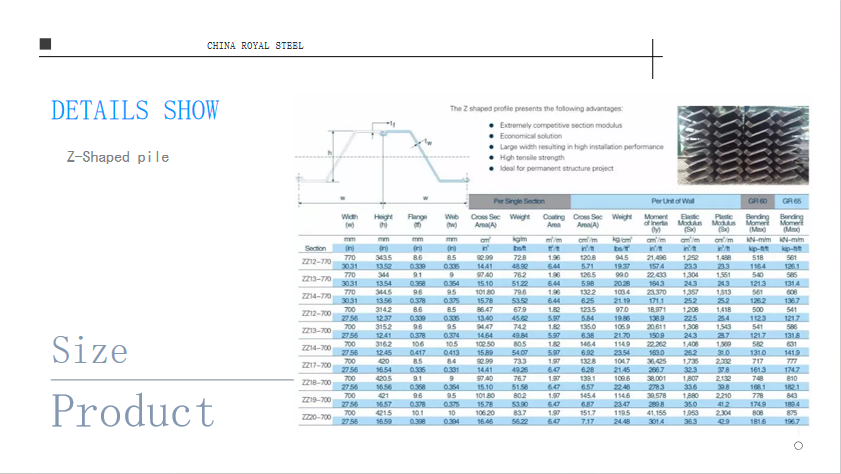

AZ50-700 AZ52-700 Z Uri ng Steel Sheet Pile

| MGA ESPISIPIKASYON | |

| 1. Sukat | 1) 635*379—700*551mm |

| 2) Kapal ng pader:4—16MM | |

| 3)Zuri ng sheet pile | |

| 2. Pamantayan: | GB/T29654-2013 EN10249-1 |

| 3.Materyal | Q235B Q345B S235 S240 SY295 S355 S340 |

| 4. Lokasyon ng aming pabrika | Tianjin,China |

| 5. Paggamit: | 1) rolling stock |

| 2) Pagbuo ng istraktura ng bakal | |

| 3Cable tray | |

| 6. Patong: | 1) Bared2) Black Painted (varnish coating) 3) yero |

| 7. Teknik: | mainit na pinagsama |

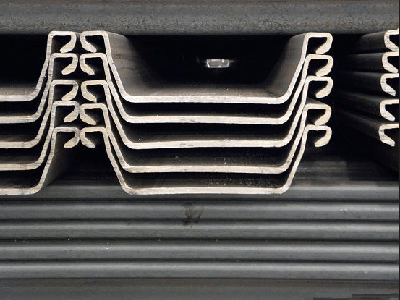

| 8. Uri: | Zuri ng sheet pile |

| 9. Hugis ng Seksyon: | Z |

| 10. Inspeksyon: | Inspeksyon o inspeksyon ng kliyente ng 3rd party. |

| 11. Paghahatid: | Lalagyan, Bulk Vessel. |

| 12. Tungkol sa Aming Kalidad: | 1) Walang pinsala, walang baluktot2) Libre para sa langis at pagmamarka 3) Ang lahat ng mga kalakal ay maaaring suriin sa pamamagitan ng third party na inspeksyon bago ipadala |

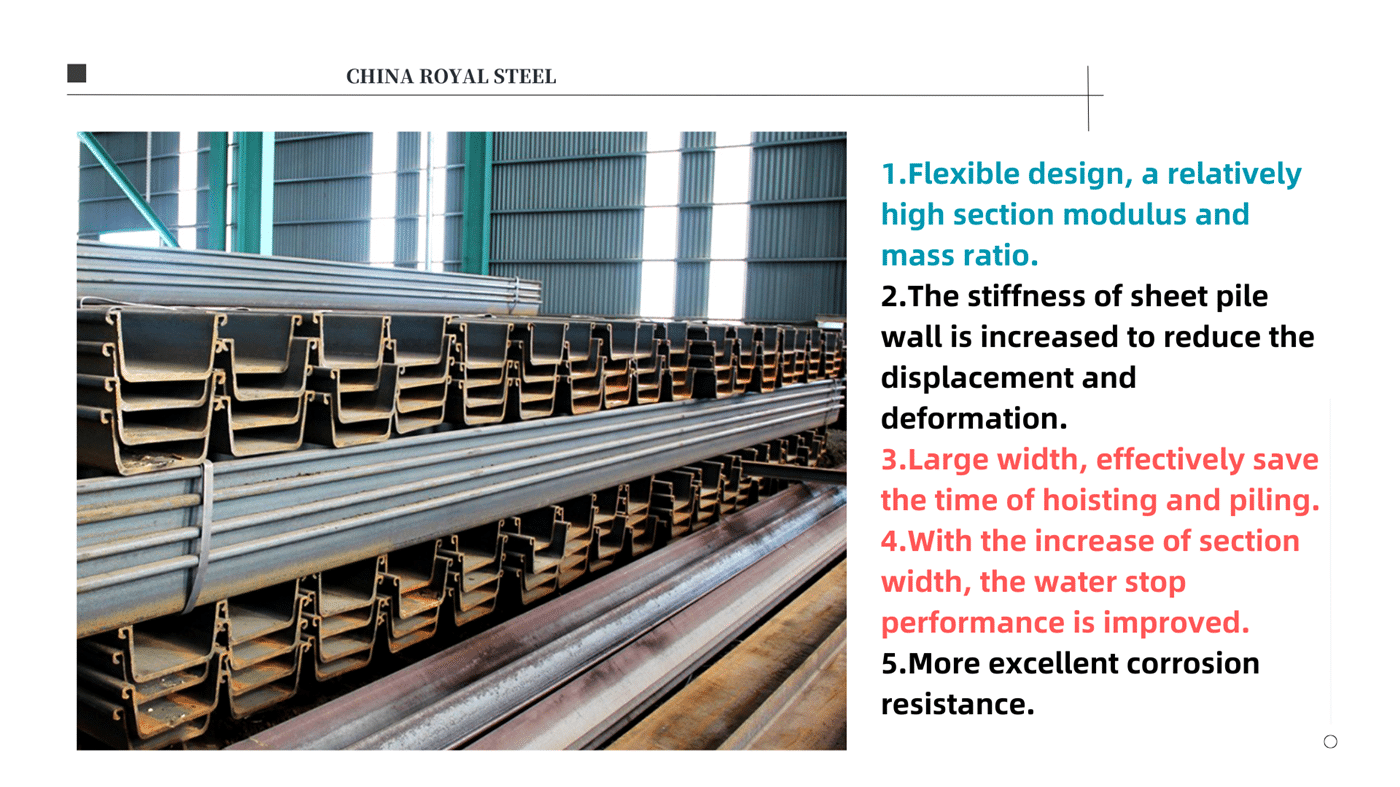

Mga tampok

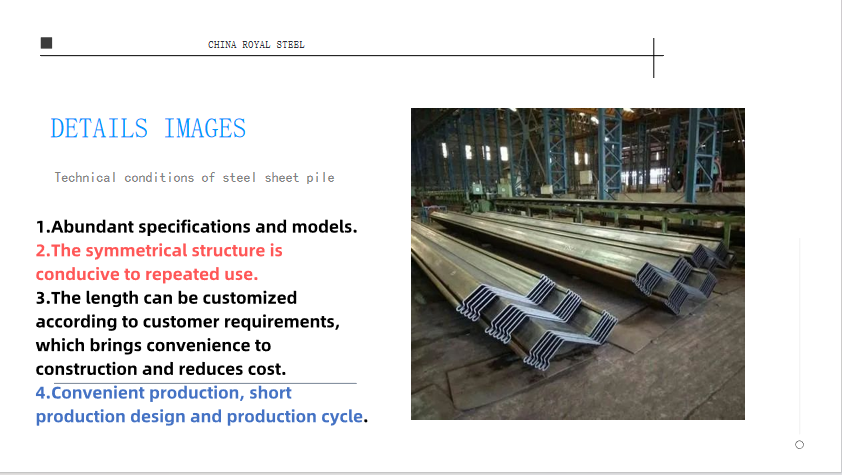

Ang Z-type na steel sheet pile ay may ilang mga tampok na ginagawang angkop ang mga ito para sa iba't ibang mga aplikasyon sa pagtatayo:

1. Hugis ng profile:Z-type na sheet pilemagkaroon ng isang natatanging profile na hugis-Z, na nagbibigay sa kanila ng mahusay na katatagan ng istruktura at kapasidad na nagdadala ng pagkarga.Ang interlocking na disenyo ay nagbibigay-daan para sa madaling pag-install at tinitiyak ang isang masikip, hindi tinatagusan ng tubig na selyo sa pagitan ng mga tambak.

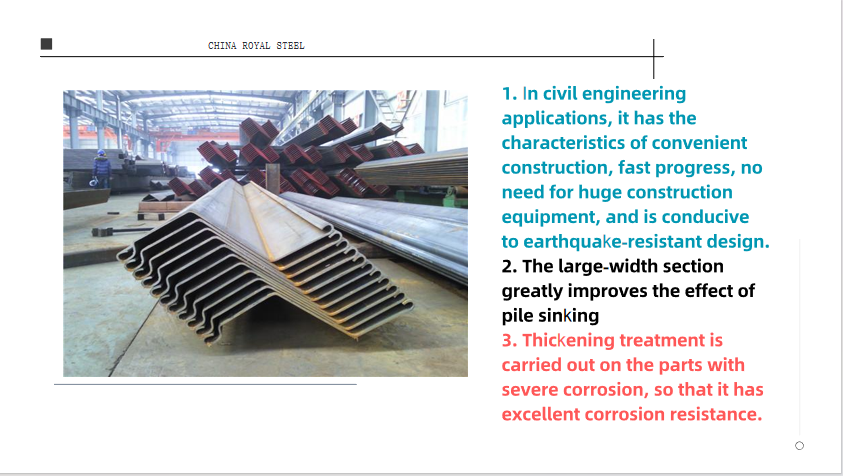

2. Mataas na lakas: Ang mga Z-type na sheet pile ay karaniwang gawa sa mataas na kalidad na bakal, na nagbibigay sa kanila ng mataas na tensile strength at tibay.Ginagawa nitong angkop ang mga ito para sa paghawak ng mabibigat na karga at paglaban sa mga panlabas na puwersa tulad ng presyon ng lupa at presyon ng tubig.

3. Interlocking mechanism: Ang Z-type na sheet piles ay nagtatampok ng mga interlocking na koneksyon sa magkabilang panig, na nagpapahintulot sa mga ito na secure na konektado at lumikha ng tuluy-tuloy na mga pader para sa iba't ibang aplikasyon.Ang mga interlock ay nagbibigay ng katatagan sa istraktura at tinitiyak ang isang mahigpit na selyo laban sa tubig at paglusot ng lupa.

4. kakayahang magamit:Z-type na sheet pileay maaaring gamitin sa iba't ibang mga sitwasyon sa pagtatayo, tulad ng mga retaining wall, flood control barrier, cofferdam, deep foundation system, marine structure, at abutment ng tulay.Ang kanilang versatility ay ginagawang naaangkop ang mga ito para sa isang malawak na hanay ng mga proyekto sa civil engineering.

5. Corrosion resistance: Upang mapahusay ang tibay ng Z-type sheet piles, maaari silang lagyan ng protective materials, tulad ng epoxy o zinc, upang magbigay ng corrosion resistance.Ito ay nagpapahintulot sa kanila na makayanan ang malupit na kondisyon sa kapaligiran, lalo na sa mga lugar sa dagat o baybayin.

6. Cost-effectiveness: Ang Z-type na sheet pile ay itinuturing na isang cost-effective na solusyon dahil sa kanilang mahabang buhay at kadalian ng pag-install.Nangangailangan sila ng kaunting pagpapanatili at maaaring magamit muli sa iba't ibang mga proyekto, na ginagawa itong isang napapanatiling pagpipilian.

7. Pag-customize: Maaaring i-customize ang Z-type na sheet pile upang umangkop sa mga partikular na kinakailangan ng proyekto.Maaari silang gawa-gawa sa iba't ibang haba, lapad, at kapal upang matugunan ang iba't ibang kondisyon ng lupa at mga pangangailangan sa istruktura.

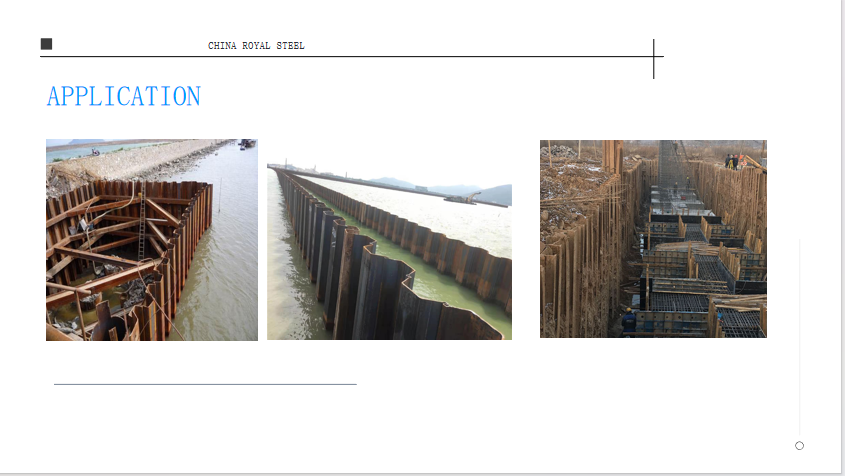

Aplikasyon

Ang Z-type na steel sheet piles ay may iba't ibang aplikasyon sa civil engineering at construction projects.Narito ang ilang karaniwang mga application:

Mga pader na nagpapanatili: Ang Z-type na sheet pile ay kadalasang ginagamit bilang retaining wall upang patatagin ang mga slope, maiwasan ang pagguho ng lupa, at magbigay ng suporta sa istruktura para sa mga paghuhukay.Maaari silang mai-install nang patayo o may bahagyang anggulo ng batter, depende sa mga partikular na kinakailangan ng proyekto.

Mga hadlang sa pagkontrol ng baha: Ang magkakaugnay na disenyo ng Z-type na sheet piles ay nagpapahintulot sa kanila na lumikha ng matibay na mga hadlang sa pagkontrol sa baha.Ang mga hadlang na ito ay ginagamit upang protektahan ang mga imprastraktura at ari-arian mula sa tubig baha at magbigay ng pansamantala o permanenteng proteksyon sa baha.

Cofferdams: Ang mga Z-type na sheet pile ay malawakang ginagamit sa pagtatayo ng mga cofferdam, na mga pansamantalang istruktura na itinayo upang ihiwalay ang isang lugar ng konstruksyon mula sa tubig habang ginagawa ang tulay o dam, mga pag-install ng pipeline, o iba pang gawain sa ilalim ng tubig.Tinitiyak ng mga interlock ang isang watertight seal upang panatilihing tuyo ang lugar ng trabaho.

Mga sistema ng malalim na pundasyon: Maaaring gamitin ang Z-type na sheet pile sa mga deep foundation system tulad ng deep excavations, basement, at underground structures.Nagbibigay sila ng mahalagang suporta upang maiwasan ang pag-ilid na paggalaw ng nakapalibot na lupa at matiyak ang katatagan ng mga pundasyon.

Mga istrukturang dagat: Ang mga Z-type na sheet pile ay angkop para sa iba't ibang istruktura ng dagat, kabilang ang mga seawall, jetties, quay wall, at breakwaters.Nakatiis ang mga ito sa haydroliko na puwersa ng tubig at nagbibigay ng solidong hadlang laban sa pagguho at epekto ng alon.

Mga abutment ng tulay: Ang Z-type na sheet pile ay karaniwang ginagamit para sa mga abutment ng tulay, na siyang mga istruktura ng diskarte sa mga dulo ng mga tulay na nagbibigay ng suporta sa bridge deck.Tumutulong sila na ipamahagi ang karga mula sa tulay hanggang sa lupa, na tinitiyak ang katatagan at pangmatagalang tibay.

Mga pansamantalang gawa: Ginagamit din ang Z-type na sheet pile para sa mga pansamantalang istruktura, tulad ng excavation shoring, trenching, at pansamantalang earth retaining wall sa panahon ng mga aktibidad sa pagtatayo.Nagbibigay sila ng ligtas at mahusay na solusyon para sa mga construction site.

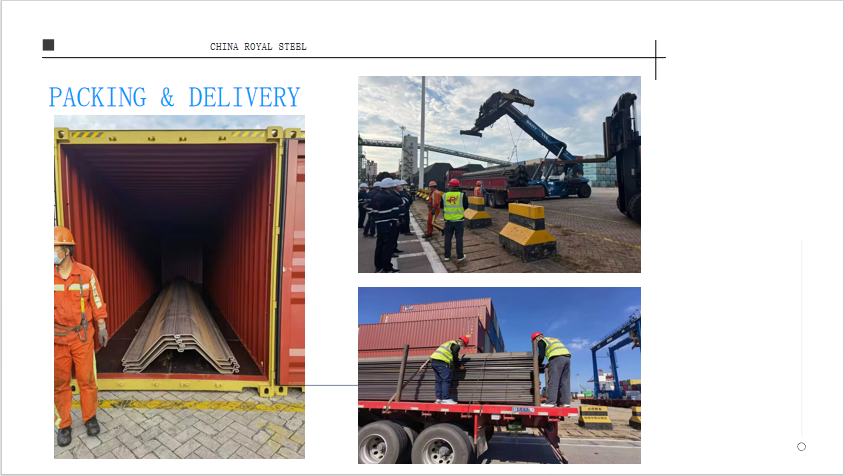

Packaging at Pagpapadala

Packaging:

I-stack ang mga sheet piles nang secure: Ayusin ang hugis-Z na sheet piles sa isang maayos at matatag na stack, na tinitiyak na ang mga ito ay nakahanay nang maayos upang maiwasan ang anumang kawalang-tatag.Gumamit ng strapping o banding upang ma-secure ang stack at maiwasan ang paglipat sa panahon ng transportasyon.

Gumamit ng mga materyal na pamproteksiyon sa packaging: I-wrap ang stack ng mga sheet pile na may moisture-resistant na materyal, tulad ng plastic o waterproof na papel, upang protektahan ang mga ito mula sa pagkakalantad sa tubig, halumigmig, at iba pang mga elemento sa kapaligiran.Makakatulong ito na maiwasan ang kalawang at kaagnasan.

Pagpapadala:

Pumili ng angkop na paraan ng transportasyon: Depende sa dami at bigat ng mga sheet piles, piliin ang naaangkop na paraan ng transportasyon, tulad ng mga flatbed truck, container, o barko.Isaalang-alang ang mga salik tulad ng distansya, oras, gastos, at anumang mga kinakailangan sa regulasyon para sa transportasyon.

Gumamit ng naaangkop na kagamitan sa pag-angat: Upang ikarga at i-unload ang hugis-U na steel sheet piles, gumamit ng angkop na kagamitan sa pag-angat gaya ng mga crane, forklift, o loader.Tiyakin na ang kagamitang ginamit ay may sapat na kapasidad upang mahawakan ang bigat ng mga sheet piles nang ligtas.

I-secure ang load: I-secure nang maayos ang nakabalot na stack ng mga sheet piles sa sasakyang pang-transportasyon gamit ang strapping, bracing, o iba pang angkop na paraan upang maiwasan ang paglilipat, pag-slide, o pagkahulog habang nagbibiyahe.

FAQ

1.Paano ako makakakuha ng quotation mula sa iyo?

Maaari kang mag-iwan sa amin ng mensahe, at tutugon kami sa bawat mensahe sa tamang oras.

2.Ihahatid mo ba ang mga kalakal sa oras?

Oo, nangangako kaming magbibigay ng pinakamahusay na kalidad ng mga produkto at paghahatid sa oras.Ang katapatan ang prinsipyo ng aming kumpanya.

3.Maaari ba akong makakuha ng mga sample bago mag-order?

Oo naman.Karaniwan ang aming mga sample ay libre, maaari kaming gumawa ng iyong mga sample o teknikal na mga guhit.

4.Ano ang iyong mga tuntunin sa pagbabayad?

Ang aming karaniwang termino sa pagbabayad ay 30% na deposito, at iba pa laban sa B/L.EXW, FOB, CFR, CIF.

5.Tinatanggap mo ba ang inspeksyon ng ikatlong partido?

Oo talagang tinatanggap namin.

6.Paano namin pinagkakatiwalaan ang iyong kumpanya?

Dalubhasa kami sa negosyong bakal sa loob ng maraming taon bilang golden supplier, ang punong-tanggapan ay matatagpuan sa lalawigan ng Tianjin, malugod kaming mag-imbestiga sa anumang paraan, sa lahat ng paraan.