GB Standard na Riles na Bakal Standard na Riles na Bakal

pakyawan na mga produkto ng rilesay gumanap ng mahalagang papel sa pag-unlad ng transportasyon, na nagbibigay-daan sa mahusay na paggalaw ng mga kalakal at tao sa malalayong distansya. Sa puso ng bawat riles ng tren ay naroon ang riles ng tren, isang matibay at maaasahang istruktura na sumusuporta sa bigat ng mga lokomotibo at mga gulong. Sa paglipas ng panahon, ang karaniwang riles na ginagamit para sa mga riles ng tren ay sumailalim sa mga makabuluhang pagbabago, kung saan ang bakal ang umuusbong bilang ang ginustong materyal.

Ang mga riles ng tren na bakal ay nagbibigay ng matatag at makinis na ibabaw para sa mga tren, na nagpapaliit sa panganib ng mga aksidente. Tinitiyak ng tibay ng bakal na hindi nababago ang hugis ng mga riles sa ilalim ng mabibigat na karga, na tinitiyak ang ligtas at siguradong paglalakbay para sa mga pasahero at kargamento.

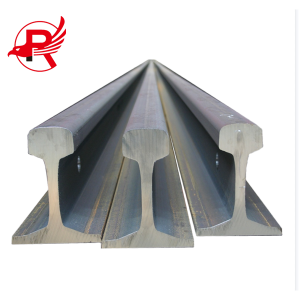

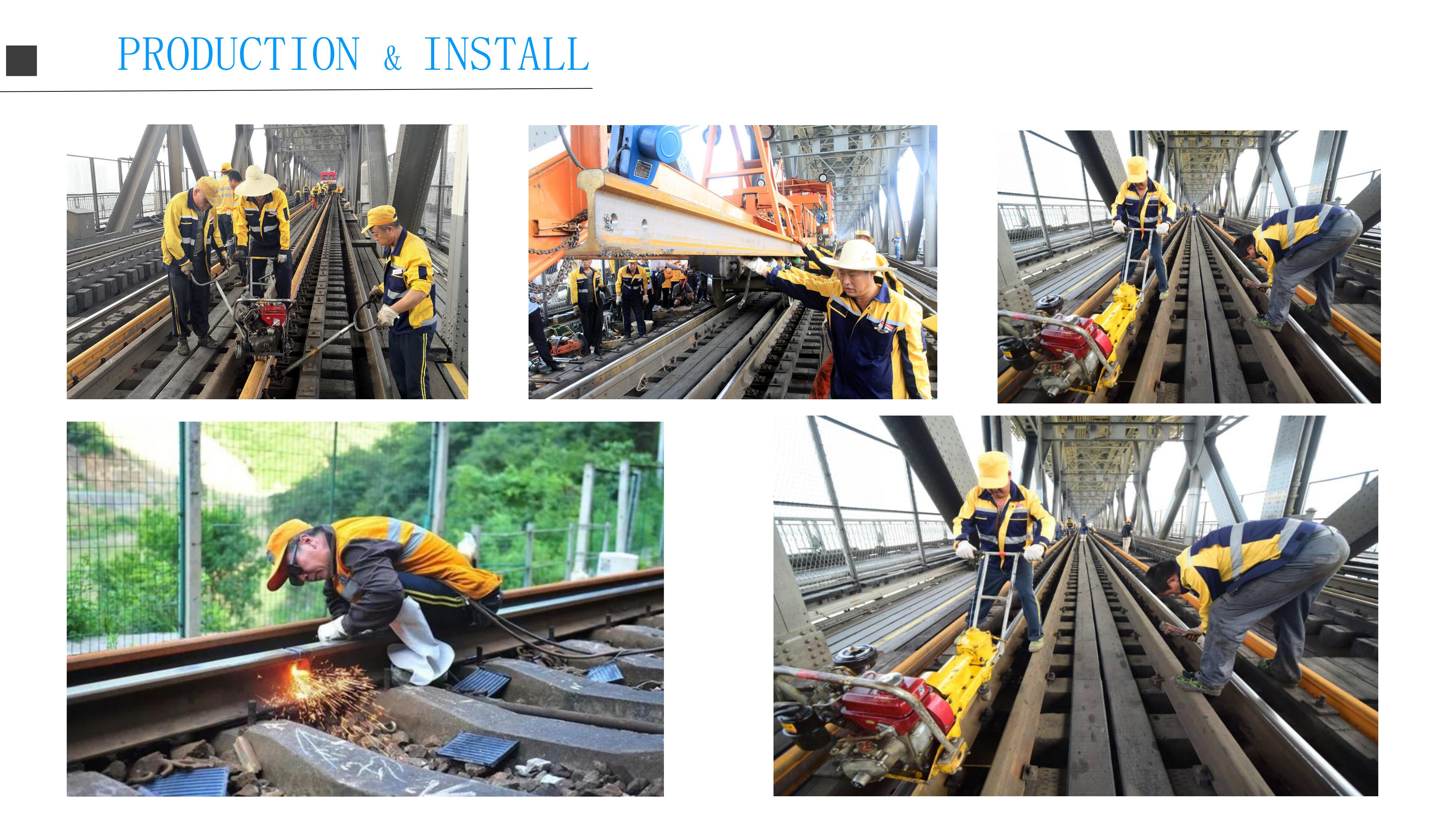

PROSESO NG PRODUKTO

Teknolohiya at Proseso ng Konstruksyon

Ang proseso ng pagbuoMga Riles ng TrenAng mga riles ay kinabibilangan ng precision engineering at maingat na pagsasaalang-alang sa iba't ibang salik. Nagsisimula ito sa pagdidisenyo ng layout ng riles, isinasaalang-alang ang nilalayong paggamit, bilis ng tren, at lupain. Kapag natapos na ang disenyo, magsisimula ang proseso ng konstruksyon sa mga sumusunod na pangunahing hakbang:

1. Paghuhukay at Pundasyon: Inihahanda ng mga tripulante ng konstruksyon ang lupa sa pamamagitan ng paghuhukay sa lugar at paglikha ng matibay na pundasyon upang suportahan ang bigat at stress na dulot ng mga tren.

2. Pag-install ng Ballast: Isang patong ng dinurog na bato, na kilala bilang ballast, ang inilalagay sa inihandang ibabaw. Ito ay nagsisilbing patong na sumisipsip ng shock, na nagbibigay ng katatagan, at tumutulong na ipamahagi nang pantay ang karga.

3. Mga Tali at Pangkabit: Ang mga tali na gawa sa kahoy o kongkreto ay inilalagay sa ibabaw ng ballast, na ginagaya ang isang istrukturang parang balangkas. Ang mga taling ito ay nagbibigay ng matibay na base para sa mga riles ng tren na bakal. Ang mga ito ay ikinakabit gamit ang mga partikular na spike o clip, tinitiyak na mananatili ang mga ito sa lugar.

4. Pag-install ng Riles: Ang mga riles ng tren na bakal na 10m, na kadalasang tinutukoy bilang mga karaniwang riles, ay maingat na inilalagay sa ibabaw ng mga pangtali. Dahil gawa sa mataas na kalidad na bakal, ang mga riles na ito ay nagtataglay ng kahanga-hangang lakas at tibay.

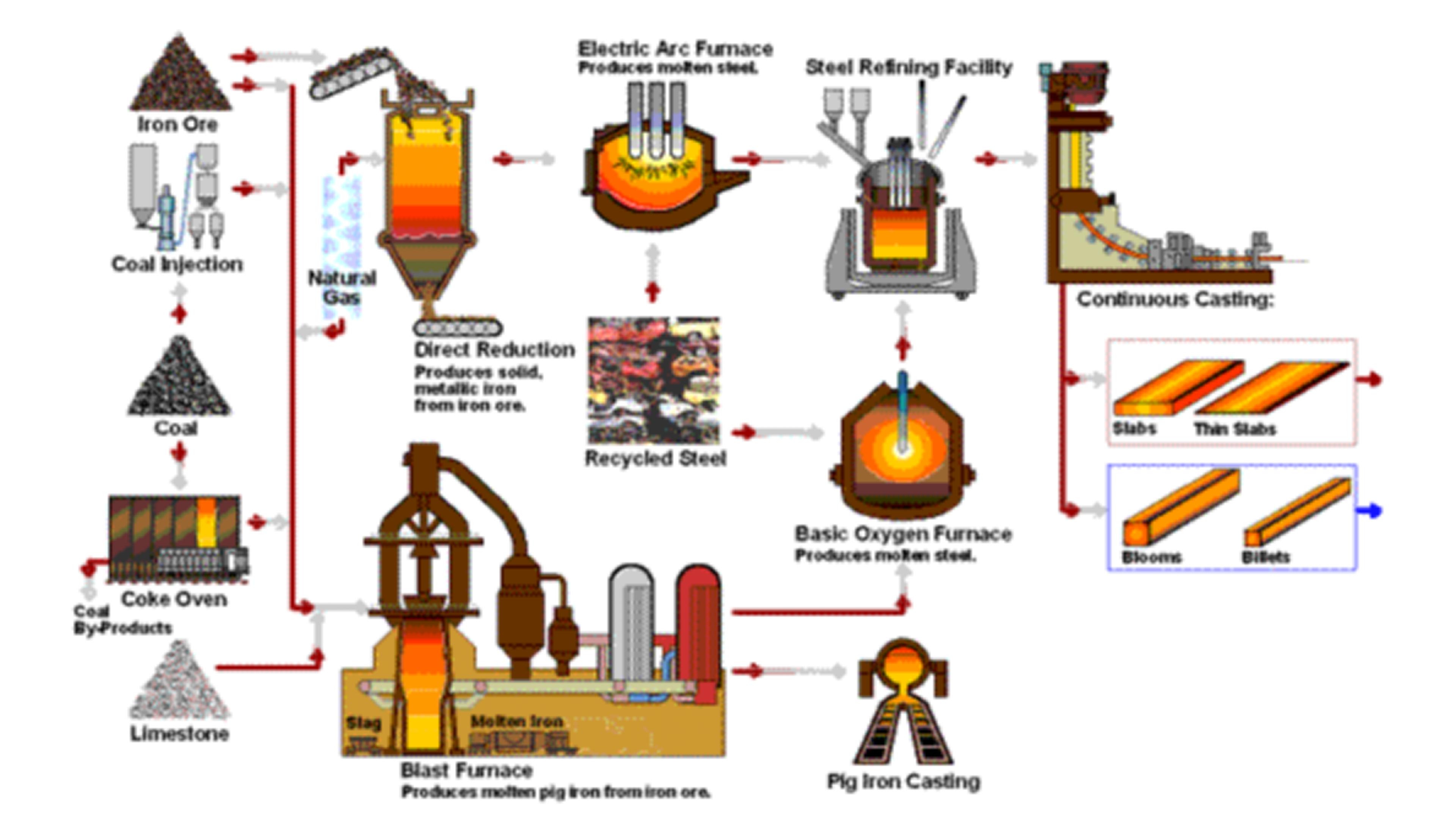

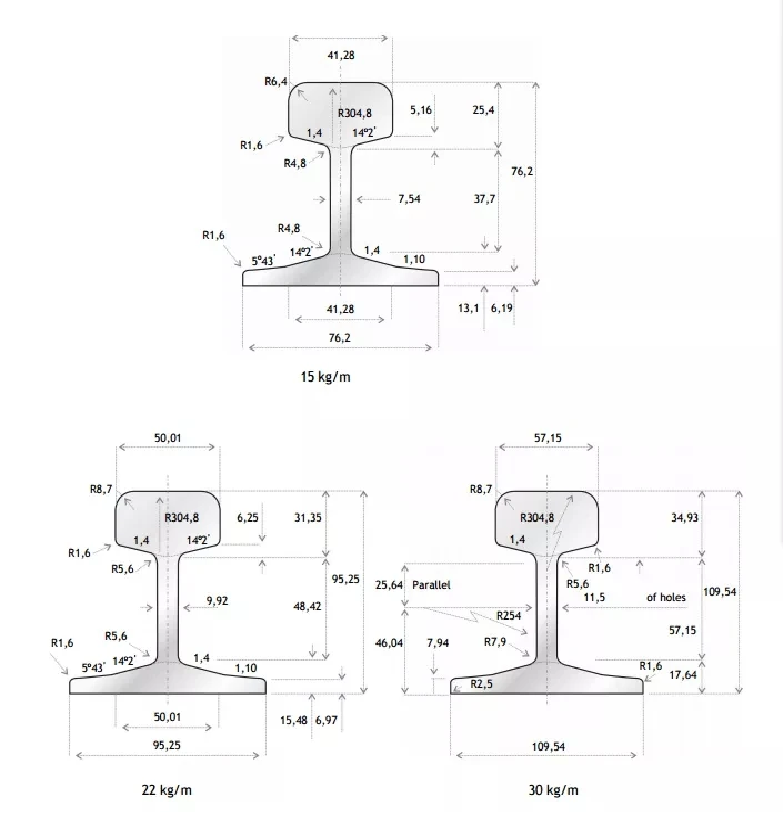

SUKAT NG PRODUKTO

| Pangalan ng Produkto: | GB Standard na Riles na Bakal | |||

| Uri: | Mabigat na Riles, Riles ng Crane,Magaan na Riles | |||

| Materyal/Espesipikasyon: | ||||

| Magaan na Riles: | Modelo/Materyal: | Q235, 55Q; | Espesipikasyon: | 30kg/m², 24kg/m², 22kg/m², 18kg/m², 15kg/m², 12 kg/m², 8 kg/m². |

| Mabigat na Riles: | Modelo/Materyal: | 45MN,71MN; | Espesipikasyon: | 50kg/m², 43kg/m², 38kg/m², 33kg/m². |

| Riles ng Kreyn: | Modelo/Materyal: | U71MN; | Espesipikasyon: | 70 kg/m², 80 kg/m², 100 kg/m², 120 kg/m². |

GB Standard na Riles na Bakal:

Mga Espesipikasyon: GB6kg, 8kg, GB9kg, GB12, GB15kg, 18kg, GB22kg, 24kg, GB30, P38kg, P43kg, P50kg, P60kg, QU70, QU80, QU100, QU120

Pamantayan: GB11264-89 GB2585-2007 YB/T5055-93

Materyal: U71Mn/50Mn

Haba: 6m-12m 12.5m-25m

| Kalakal | Baitang | Sukat ng Seksyon (mm) | ||||

| Taas ng Riles | Lapad ng Base | Lapad ng Ulo | Kapal | Timbang (kg) | ||

| Magaan na Riles | 8KG/M | 65.00 | 54.00 | 25.00 | 7.00 | 8.42 |

| 12KG/M | 69.85 | 69.85 | 38.10 | 7.54 | 12.2 | |

| 15KG/M | 79.37 | 79.37 | 42.86 | 8.33 | 15.2 | |

| 18KG/M | 90.00 | 80.00 | 40.00 | 10.00 | 18.06 | |

| 22KG/M | 93.66 | 93.66 | 50.80 | 10.72 | 22.3 | |

| 24KG/M | 107.95 | 92.00 | 51.00 | 10.90 | 24.46 | |

| 30KG/M | 107.95 | 107.95 | 60.33 | 12:30 | 30.10 | |

| Mabigat na Riles | 38KG/M | 134.00 | 114.00 | 68.00 | 13.00 | 38.733 |

| 43KG/M | 140.00 | 114.00 | 70.00 | 14.50 | 44.653 | |

| 50KG/M | 152.00 | 132.00 | 70.00 | 15.50 | 51.514 | |

| 60KG/M | 176.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| 75KG/M | 192.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| UIC54 | 159.00 | 140.00 | 70.00 | 16.00 | 54.43 | |

| UIC60 | 172.00 | 150.00 | 74.30 | 16.50 | 60.21 | |

| Pag-angat ng Riles | QU70 | 120.00 | 120.00 | 70.00 | 28.00 | 52.80 |

| QU80 | 130.00 | 130.00 | 80.00 | 32.00 | 63.69 | |

| QU100 | 150.00 | 150.00 | 100.00 | 38.00 | 88.96 | |

| QU120 | 170.00 | 170.00 | 120.00 | 44.00 | 118.1 | |

BENTAHA

Mga Tampok ngMga Riles ng Tren

1. Malakas na kapasidad sa pagdadala ng karga: Ang mga riles na bakal ang pangunahing bahagi ng mga high-speed na tren. Dinadala nila ang bigat at karga ng tren, at natitiis ang pagtama at alitan ng presyon ng atmospera, lindol at iba pang mga sasakyan at natural na karga.

2. Mahusay na resistensya sa pagkasira: Ang ibabaw ng riles ay gawa sa mga materyales na hindi tinatablan ng pagkasira, na may mahusay na mga katangiang anti-pagkasira at kayang labanan ang pagkasira ng mga set ng gulong ng tren at mabibigat na kargamento, na nagpapahaba sa buhay ng serbisyo nito.

3. Malakas na resistensya sa kalawang: Ang ibabaw ng riles ay tinatrato ng mga materyales na lumalaban sa kalawang, na may mahusay na resistensya sa kalawang at maaaring gamitin nang mahabang panahon sa ilalim ng iba't ibang kondisyon ng klima.

4. Maunlad na teknolohiya sa pagmamanupaktura: Ang mga riles ay ginawa gamit ang maunlad na teknolohiya sa pagmamanupaktura at kagamitan sa produksyon, at may mga bentahe sa teknolohiya, kalidad, hitsura, atbp.

PROYEKTO

Ang aming kumpanya'Ang 13,800 tonelada ng mga riles na bakal na iniluluwas sa Estados Unidos ay ipinadala sa Daungan ng Tianjin nang sabay-sabay. Natapos ang proyekto ng konstruksyon at ang huling riles ay tuluy-tuloy na inilatag sa linya ng riles. Ang mga riles na ito ay pawang mula sa pangkalahatang linya ng produksyon ng aming pabrika ng riles at bakal na beam, gamit ang pandaigdigang produksyon ayon sa pinakamataas at pinakamahigpit na pamantayang teknikal.

Para sa karagdagang impormasyon tungkol sa mga produktong pang-riles, mangyaring makipag-ugnayan sa amin!

WeChat: +86 13652091506

Tel: +86 13652091506

Email:[email protected]

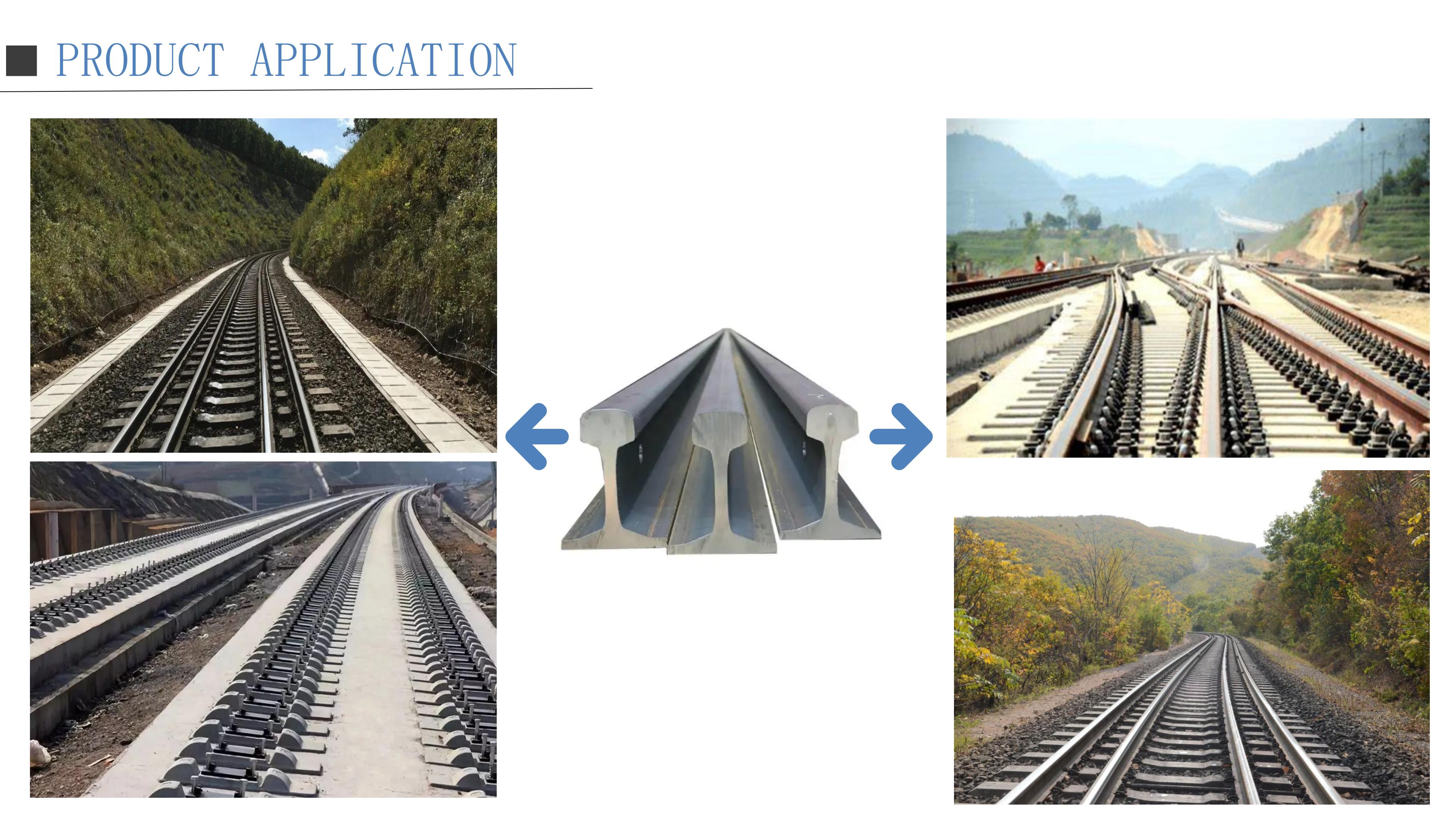

APLIKASYON

Upang magawa angRiles ng TrenKung sapat ang katatagan, ang lapad ng riles ay dapat piliin nang pinakamalapad hangga't maaari kapag nagdidisenyo ng lapad ng riles. Upang pinakamahusay na tumugma sa higpit at katatagan, karaniwang kinokontrol ng mga bansa ang ratio ng taas ng riles sa lapad sa ilalim, na H/B, kapag nagdidisenyo ng seksyon ng riles. Sa pangkalahatan, ang H/B ay kinokontrol sa pagitan ng 1.15 at 1.248. Ang mga halaga ng H/B ng mga riles sa ilang mga bansa ay ipinapakita sa talahanayan.

PAG-EMBAL AT PAGPAPADALA

Ang mga riles ng tren na bakal ay gumanap ng mahalagang papel sa pagsulong ng mga modernong riles ng tren. Ang kanilang tibay, tibay, mababang pangangailangan sa pagpapanatili, at mga katangiang pangkaligtasan ang dahilan kung bakit sila ang pinipiling pagpipilian para sa imprastraktura ng riles. Habang umuunlad ang kontemporaryong transportasyon, patuloy na tinitiyak ng mga riles ng tren na bakal ang maayos at mahusay na operasyon ng mga network ng tren sa buong mundo. Sa patuloy na pananaliksik at pag-unlad, ang hinaharap ay nangangako ng mas makabago at napapanatiling mga solusyon na higit pang magpapahusay sa pagganap at pagpapanatili ng mga riles ng tren.

LAKAS NG KOMPANYA

Gawa sa Tsina, serbisyong primera klase, makabagong kalidad, kilala sa buong mundo

1. Epekto sa iskala: Ang aming kumpanya ay may malaking supply chain at malaking pabrika ng bakal, na nakakamit ng mga epekto sa iskala sa transportasyon at pagkuha, at nagiging isang kumpanya ng bakal na nagsasama ng produksyon at mga serbisyo.

2. Pagkakaiba-iba ng produkto: Pagkakaiba-iba ng produkto, anumang bakal na gusto mo ay mabibili sa amin, pangunahin na nakatuon sa mga istrukturang bakal, mga riles ng bakal, mga pile ng bakal, mga photovoltaic bracket, channel steel, mga silicon steel coil at iba pang mga produkto, na ginagawang mas nababaluktot. Piliin ang nais na uri ng produkto upang matugunan ang iba't ibang pangangailangan.

3. Matatag na suplay: Ang pagkakaroon ng mas matatag na linya ng produksyon at supply chain ay maaaring magbigay ng mas maaasahang suplay. Ito ay lalong mahalaga para sa mga mamimili na nangangailangan ng malaking dami ng bakal.

4. Impluwensya ng tatak: Magkaroon ng mas mataas na impluwensya ng tatak at mas malaking merkado

5. Serbisyo: Isang malaking kompanya ng bakal na nagsasama ng pagpapasadya, transportasyon at produksyon

6. Kakayahang makipagkumpitensya sa presyo: makatwirang presyo

*Ipadala ang email sa[email protected]para makakuha ng quotation para sa iyong mga proyekto

BUMISITA ANG MGA KUSTOMER

Mga Madalas Itanong

Mga Madalas Itanong

1. Paano ako makakakuha ng sipi mula sa iyo?

Maaari kang mag-iwan ng mensahe sa amin, at sasagutin namin ang bawat mensahe sa tamang oras.

2. Ihahatid mo ba ang mga kalakal sa oras?

Oo, ipinapangako naming magbibigay ng pinakamahusay na kalidad ng mga produkto at paghahatid sa tamang oras. Katapatan ang prinsipyo ng aming kumpanya.

3. Maaari ba akong makakuha ng mga sample bago mag-order?

Oo, siyempre. Kadalasan, libre ang aming mga sample, maaari kaming gumawa gamit ang iyong mga sample o teknikal na mga guhit.

4. Ano ang iyong mga tuntunin sa pagbabayad?

Ang aming karaniwang termino ng pagbabayad ay 30% na deposito, at ang natitira ay ang B/L. EXW, FOB, CFR, CIF.

5. Tinatanggap mo ba ang inspeksyon ng ikatlong partido?

Oo, tinatanggap namin nang lubusan.

6. Paano namin pinagkakatiwalaan ang inyong kompanya?

Dalubhasa kami sa negosyo ng bakal sa loob ng maraming taon bilang ginintuang tagapagtustos, ang punong-tanggapan ay matatagpuan sa lalawigan ng Tianjin, malugod kaming tinatanggap na mag-imbestiga sa anumang paraan, sa lahat ng paraan.